The Digital Revolution in Rail Logistics

The rail industry, with its rich history dating back to the industrial revolution, has often been perceived as traditional and slow to change. However, a digital revolution is transforming railway logistics in the United Kingdom and beyond, going far beyond simple shipment tracking to fundamentally reimagine how the entire logistics ecosystem operates.

This digital transformation is creating new possibilities for efficiency, customer service, sustainability, and business models. At Northern Railway Logistics, we're at the forefront of these developments, leveraging cutting-edge technologies to deliver exceptional service while driving innovation throughout the sector.

Beyond Basic Tracking: The New Digital Landscape

When most people think of digitalization in logistics, their first thought is tracking—knowing where a shipment is at any given moment. While this remains important, today's digital transformation encompasses a much broader range of technologies and applications:

Internet of Things (IoT)

Connected sensors providing real-time data on location, condition, and environment of goods and assets

Artificial Intelligence

Machine learning algorithms optimizing routing, predicting maintenance needs, and enhancing customer service

Blockchain

Distributed ledger technology providing secure, transparent documentation and payment processing

Cloud Computing

Scalable infrastructure enabling collaboration across the supply chain and integration of disparate systems

Big Data Analytics

Advanced data processing revealing patterns and insights for continuous improvement

AR/VR Technology

Immersive technologies enhancing training, maintenance, and operations

The integration of these technologies is creating a digital ecosystem that is fundamentally changing how railway logistics operates. Let's explore the key areas of transformation:

Intelligent Asset Management

One of the most significant impacts of digitalization is on the management of rail assets—locomotives, wagons, infrastructure, and facilities. Smart sensors and IoT connectivity are enabling:

Predictive Maintenance

Traditional maintenance schedules often follow fixed intervals, which can lead to either premature maintenance (wasting resources) or maintenance performed too late (risking failures). Digital technologies are transforming this approach:

- IoT sensors continuously monitor equipment conditions, including temperature, vibration, and acoustic signatures

- AI algorithms analyze patterns to detect anomalies before they cause failures

- Maintenance can be scheduled precisely when needed, maximizing asset availability

- Digital twins (virtual replicas of physical assets) enable simulation and testing of maintenance strategies

Engineer using a tablet with predictive maintenance software to analyze locomotive performance data.

Northern Railway Logistics has implemented predictive maintenance across our fleet, resulting in a 32% reduction in unplanned downtime and a 24% decrease in maintenance costs over the past two years.

Dynamic Fleet Management

Digital technologies are enabling more efficient use of rolling stock and other assets:

- Real-time location and status monitoring of all rail vehicles

- Automated rebalancing of assets based on demand forecasts

- Digital routing optimization to maximize asset utilization

- Performance analytics to identify and address inefficiencies

These capabilities have allowed us to increase our fleet utilization by 18%, effectively expanding our capacity without purchasing additional locomotives or wagons.

Intelligent Network Management

Beyond individual assets, digital technologies are transforming how the entire rail network is managed:

Traffic Management Systems

Advanced digital traffic management systems are revolutionizing rail operations:

- AI-powered conflict detection and resolution to prevent bottlenecks

- Dynamic rescheduling capabilities that respond to disruptions in real-time

- Integration with weather data and other external factors to anticipate issues

- Driver advisory systems providing real-time guidance for optimal speeds and energy usage

These systems are particularly valuable in the congested UK rail network, where passenger and freight services share the same infrastructure. By optimizing traffic flow, they increase capacity without requiring costly physical infrastructure expansion.

Digital Signaling

The European Train Control System (ETCS) and related digital signaling technologies are fundamentally changing how trains operate:

- Moving from fixed block to moving block signaling increases line capacity

- Continuous digital communication between trains and control centers enhances safety

- Automated train operation capabilities reduce human error and improve consistency

- Interoperability across different networks streamlines cross-border operations

"The implementation of digital signaling and traffic management systems represents the biggest transformation in railway operations since the transition from steam to diesel and electric traction. It's not just an upgrade—it's a complete reimagining of how the network functions."

David Patel, CTO, Northern Railway Logistics

Customer Experience Transformation

While operational improvements are critical, the digital transformation of railway logistics is also revolutionizing the customer experience:

End-to-End Visibility

Today's customers expect complete transparency in their logistics operations:

- Real-time tracking of shipments across the entire journey, including multimodal connections

- Environmental condition monitoring for sensitive goods

- Proactive alerts about potential delays or issues

- Historical analytics providing insights into performance patterns

Our digital platform provides customers with unprecedented visibility into their supply chains, enabling better planning and reducing the need for safety stock.

Northern Railway Logistics' digital customer platform showing real-time shipment tracking and analytics.

Digital Booking and Documentation

The paperwork that traditionally accompanied rail freight is being rapidly digitalized:

- Online booking platforms with instant capacity confirmation and pricing

- Digital consignment notes and customs documentation

- Blockchain-secured document exchange eliminating fraud risks

- Automated customs clearance procedures reducing border delays

These digital solutions have reduced our document processing time by 87% and virtually eliminated paperwork errors, which were previously a significant cause of delays.

API Integration

Perhaps most transformatively, our systems now directly connect with customer systems through APIs (Application Programming Interfaces):

- Direct integration with customer ERP and warehouse management systems

- Automated booking based on inventory levels or production schedules

- Real-time data sharing across the supply chain

- Custom dashboards tailored to specific customer requirements

This deep integration is transforming railway logistics from a discrete service to a seamless extension of our customers' operations.

Data-Driven Decision Making

The increasing digitalization of railway logistics is generating vast amounts of data, which in turn is enabling more sophisticated decision-making:

Predictive Analytics

Advanced analytics are helping us anticipate and prepare for future demands:

- Demand forecasting based on historical patterns, seasonal factors, and economic indicators

- Network flow optimization to minimize empty runs and maximize capacity utilization

- Disruption prediction and impact assessment to enhance resilience

- Dynamic pricing models that adjust to capacity availability and demand levels

Operational Optimization

Data analytics are driving continuous improvement in daily operations:

- Route optimization to minimize fuel consumption and transit times

- Terminal optimization to reduce dwell times and improve throughput

- Crew scheduling optimization to enhance efficiency and compliance

- Energy management to reduce costs and environmental impact

By leveraging these capabilities, we've reduced our fuel consumption by 8% and improved on-time performance by 14% over the past year.

New Business Models

Beyond improving existing operations, digital transformation is enabling entirely new business models in railway logistics:

Logistics-as-a-Service (LaaS)

Digital platforms are enabling more flexible service offerings:

- On-demand capacity booking without long-term commitments

- Virtual freight forwarding integrating multiple carriers and modes

- Subscription-based logistics services with predictable pricing

- Value-added digital services such as carbon footprint calculation and optimization

Digital Marketplaces

Platform business models are creating new ways to match supply and demand:

- Digital freight exchanges connecting shippers with available capacity

- Spot market platforms for last-minute capacity needs

- Collaborative logistics platforms enabling capacity sharing between companies

- Intermodal booking platforms providing seamless connections between rail and other modes

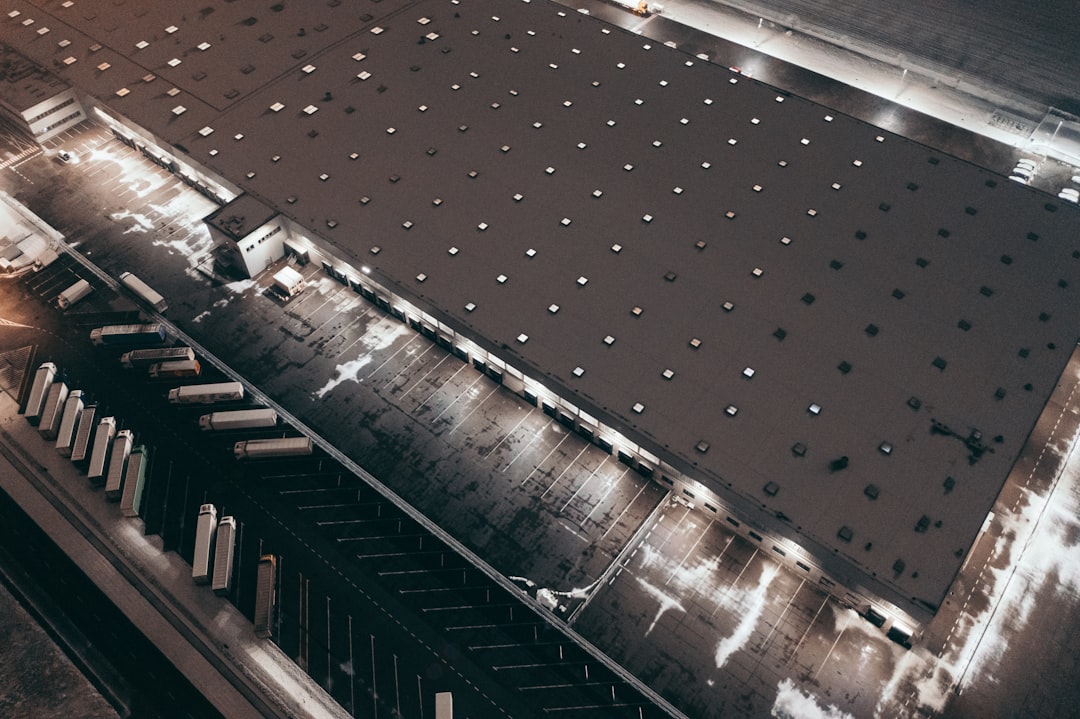

Example of a digital logistics marketplace connecting shippers with available rail capacity.

Challenges and Implementation Considerations

While the benefits of digital transformation are clear, the journey is not without challenges:

Legacy System Integration

The rail industry has many legacy systems that must be integrated or replaced:

- Middleware solutions bridging old and new systems

- Phased migration approaches minimizing operational disruption

- API layers enabling connectivity without full replacement

- Data standardization to ensure interoperability

Cybersecurity

As railway systems become more digital, they also become potential targets for cyber attacks:

- Advanced threat detection and prevention systems

- Regular security audits and penetration testing

- Secure-by-design principles in all digital developments

- Staff training and awareness programs

Skills and Culture

Digital transformation is as much about people as it is about technology:

- Upskilling existing staff to work effectively with new technologies

- Recruiting digital talent into traditionally non-tech-focused roles

- Creating a culture that embraces data-driven decision making

- Change management to ensure successful adoption

The Future: Emerging Technologies

Looking ahead, several emerging technologies are poised to further transform railway logistics:

Autonomous Operations

While fully autonomous mainline freight trains may still be some years away in mixed traffic environments, automation is advancing:

- Yard operations automation reducing handling times and increasing safety

- Driver assistance systems enhancing efficiency and consistency

- Remote operation capabilities for specific scenarios

- Platooning technologies allowing multiple trains to operate as a single unit

Advanced Materials and 3D Printing

Digital manufacturing technologies will impact the maintenance and spare parts ecosystem:

- On-demand printing of spare parts reducing inventory requirements

- Digital parts catalogs streamlining maintenance operations

- Smart materials with self-monitoring capabilities

- Lighter, stronger components improving energy efficiency

5G and Advanced Connectivity

The next generation of connectivity will enable new capabilities:

- High-bandwidth, low-latency communications enabling more sophisticated applications

- Edge computing bringing processing power closer to sensors and devices

- Massive IoT deployments with thousands of connected devices per train and along tracks

- Enhanced video analytics for safety and security applications

Northern Railway Logistics' Digital Journey

At Northern Railway Logistics, our digital transformation is well underway. Our comprehensive digital strategy includes:

- A fully integrated digital platform connecting all aspects of our operations

- IoT deployment across our entire fleet for real-time monitoring and analysis

- Advanced customer portal with API integration capabilities

- AI-powered predictive maintenance and network optimization

- Digital document processing with blockchain security

These investments are already delivering significant benefits to our customers through improved reliability, increased transparency, and enhanced efficiency. As we continue our digital journey, we remain committed to leading innovation in railway logistics across the United Kingdom.

Conclusion: The Digital Imperative

The digital transformation of railway logistics is not just a trend—it's an imperative for companies that want to remain competitive in an increasingly demanding market. The technologies discussed in this article are already revolutionizing how rail freight operates, creating new possibilities for efficiency, sustainability, and customer service.

For businesses looking to optimize their supply chains, embracing these digital logistics solutions offers significant advantages. By partnering with forward-thinking providers like Northern Railway Logistics, companies can leverage these technologies to create more resilient, efficient, and sustainable logistics operations.

The future of railway logistics is digital, and that future is arriving faster than many expected. At Northern Railway Logistics, we're proud to be helping shape this future, and we invite our customers and partners to join us on this transformative journey.

Comments (9)

Thomas Williams

May 14, 2023 at 11:20 AMGreat insights into how digital transformation is reshaping the industry. I'm particularly interested in the API integration aspects. How difficult is it to integrate with older ERP systems that many UK manufacturers still use?

Robert Davies

May 14, 2023 at 3:45 PMGreat question, Thomas. Integration with legacy ERP systems can indeed be challenging, but we've developed middleware solutions specifically designed for this purpose. Our approach typically involves creating a custom API adapter layer that translates between modern REST APIs and older integration methods like EDI or file-based transfers. For most customers, we can achieve full integration within 4-8 weeks, depending on the complexity of their systems.

Angela Chen

May 15, 2023 at 9:30 AMI'm interested in the cybersecurity aspects mentioned. With railways being classified as critical infrastructure, what specific measures are being taken to protect these increasingly digital systems from cyber threats?

Mark Johnson

May 16, 2023 at 2:15 PMThe predictive maintenance capabilities sound impressive. Are you able to share any specific examples or case studies of how this has prevented failures or improved asset availability?

Leave a Comment